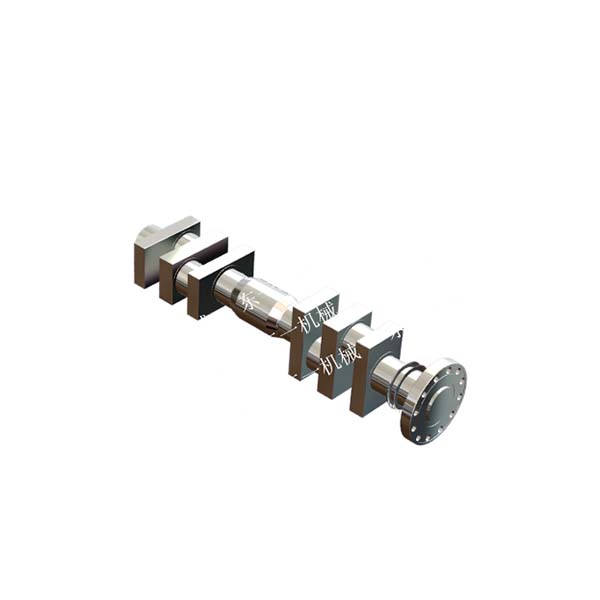

Crankshaft:a most important element of compressor,normally die forged by medium carbon steel or medium carbon alloy steel.To improve resistance to abrasion and fatigue,journal is processed with high-frequency quenching or nitriding treatment,as well as ground finishing to obtain high surface hardness and surface roughness.Under cooperation with connecting rod,it turns the gas pressure on piston into the power of rotation,and transferred to the transmission mechanism of chassis,and meanwhile,to drive the actuating mechanism and other auxiliary devices,such as blower fan,pump and power generator etc.

When in operation,it bears gas pressure,inertia force and inertia moment.It suffers form great and sophisticated stress,and as well as the impact effect of alternating load.Meanwhile,being a fast rotating component,it should be provided with enough rigidity and strength,outstanding ability to bear impact load,and excellent abrasion resistance and lubrication.

Crank is the connecting part between main journal and connecting rod journal,with cross-section being and oval.To balance the inertia force,there is a balance weight cast(or fastened) on the crank.The balance weight is used to balance the unbalanced centrifugal moment of compressor,and sometimes used to balance a part of reciprocating inertia force,thus to keep the crank running smoothly.